Film Extruction lamination

Film Lamination

- Design, Finishing, Sales for flexible packing material

- Integrated production from extruction lamination to slit

- Unique easy peel top material

- Small lot, Short delivery on standard products

Business

Department

Chubu Nihon Lami dept (Moriyama Plant)

Moriyama Plant

Moriyama Plant

Area:1,672㎡

Building:987㎡

Main Equipment

| Equipment | The number of |

|---|---|

| Extrusion Laminator | 2 |

| Slitter | 3 |

| Half Cut | 1 |

| Winching Inspector | 1 |

| Aging Box | 2 |

Products

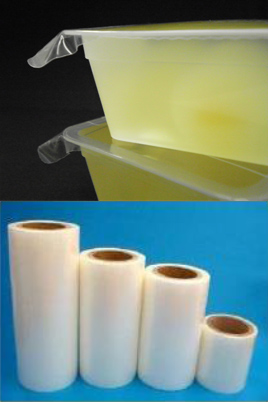

Film Lamination and Others

Easy Open Standard Film (Our Unique Products)

NL27F75 (Heat Resistance type)

| <Point> | Material: nylon 15 micron / polyolefin 60 micron Separation; cohesion separation Sterilizing is possible until 120℃ 30 min (with full filling). On full filling condition, until 85℃ 30 min Heat sealable to PP package. |

|---|---|

| <Use> | Jelly, Chawanmushi, Yokan, Steamed Egg Tofu |

NLE75, NLE90 (General type)

| <Point> | Material: nylon 15 micron / polyolefin 60 micron (NLE90: 75 micron) Separation; surface separation Sterilizing is possible until 90℃ 30 min (with full filling). Heat seal temperature range is wide because of EVA including. Heat sealable for PP, PS packaging. |

|---|---|

| <Use> | Jelly, Pudding, Steamed Egg Tofu |

BNLE90 (Barrier Type)

| <Point> | Material: barrier nylon 15 micron / polyolefin 75 micron Separation; surface separation Barrier type of NLE90. Surface substrate is barrier nylon. Heat sealable for PP, PS packaging. |

|---|---|

| <Use> | Jelly, Pudding, Steamed Egg Tofu |